* Medical & Pharmaceutical

* Engineering Polymers

* Semi-Finished Products

* Oil & Gas

* Wire & Cable

* Tube & Hose

* Automotive

* Packaging

Fluorocarbons and High-temperature Tubing Extrusion Lines

More and more industries and applications are using Fluorocarbons and High-Temperature Materials because of their superior

properties such as abrasion resistance, low-friction, and chemical resistance including:

* Medical & Pharmaceutical

* Engineering Polymers

* Semi-Finished Products

* Oil & Gas

* Wire & Cable

* Tube & Hose

* Automotive

* Packaging

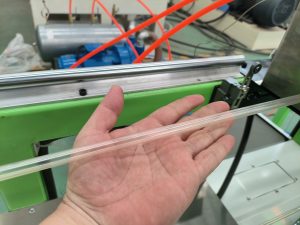

The main equipment components: heat shrinkable tube extruder – extrusion mold – cooling&shaping water tank -roll tractor Auxiliary Machine; Winder Machine&Plying Machine, Splitter

Model SJ-30 for Φ0.5-Φ10mm, 5-20mtrs/min

Model SJ-45 for Φ6-Φ20mm, 8-40mtrs/min

The main equipment components: heat shrinkable tube extruder – extrusion mold – cooling&shaping water tank-belt tractor–winding machine

Model SJ-50 for Φ20-Φ40mm, 5-20mtrs/min

Model SJ-55 for Φ30-Φ60mm, 5-18mtrs/min

The main equipment components: heat shrinkable tube extruder – extrusion mold – cooling&shaping water tank-belt tractor–winding machine/winding machine&plying machine Model SJ-65 for Φ60-Φ120mm, 4-10mtrs/min

Model SJ-75 for Φ100-Φ180mm, 4-10mtrs/min

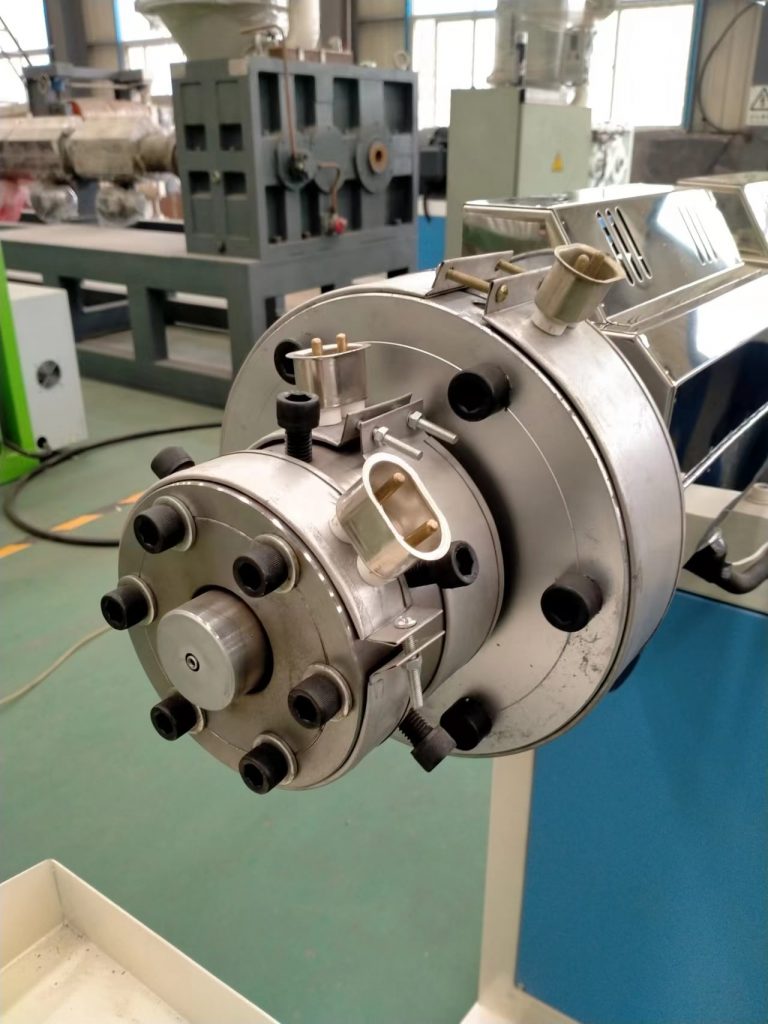

The main equipment components:

heat shrinkable tube extruder – extrusion mold – cooling&shaping water tank-belt tractor-winding machine&plying machine/cutting machine

Model SJ-90 for Φ150-260mm, 3–10mtrs/min

Model SJ-120 for Φ200-Φ300mm, 3-10mtrs/min

Heat Shrink Expansion Production Line

Expander/Expansion Line for Thin Wall Heat Shrink Tubing

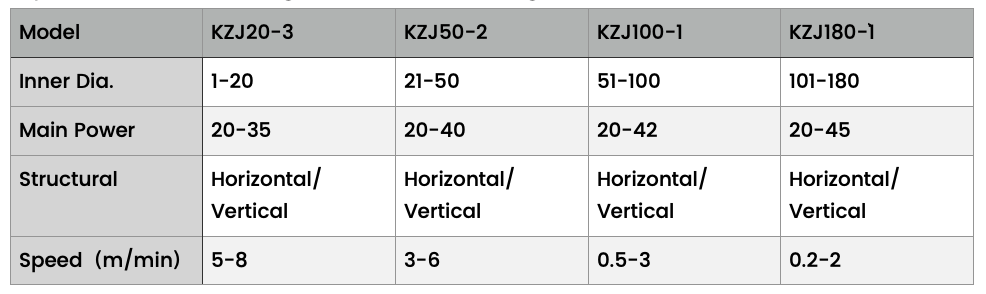

KZJ20-3 1 out of 3 Single-Wall Expansion Machine

The kind of Expander can expand three different specifications or three tubes of the same specification at the same time KZJ50-2The kind of Expander can expand two different specifications or two tubes of the same specification at the same time

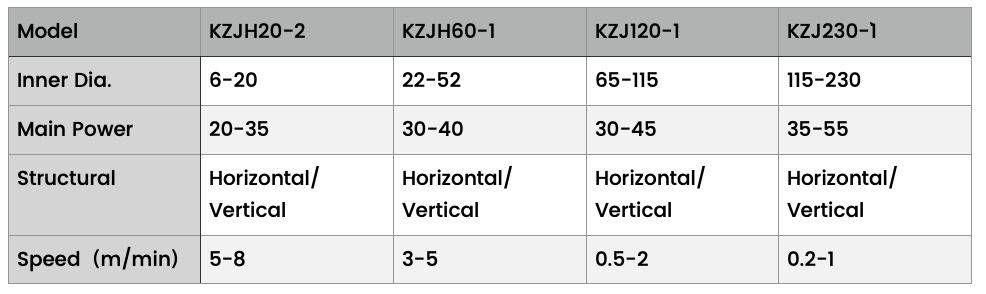

Heat Shrink Expansion Production Line

Expander/Expansion Line for Thin Wall Heat Shrink Tubing

Heat shrinkable tubing expansion production line equipment introduction:

pressure (vacuum) and positive pressure (inner air).

It mainly consists of the following parts:

1. Unwinding stand: made of the square tube or section steel, the unwinding reel rotates freely on it

2. Tube billet traction and feeding part: driven by the motor, the rubber roller feeds the tube billet into the glycerin box

3. Glycerin heating box: electric heating of glycerin to heat the tube blank, so that the irradiated tube blank reaches a molten high-elastic state

4. The conveying part of the glycerin heating box: the transmission part is driven by the motor to realize the continuous and uniform transportation of the tube billet in the glycerin box

5. Mold positioning part: used to install expansion mold

6. Vacuum control part: control the vacuum size of the mold

7. Water cooling part: control the water volume of the mold, and cool the expanded heat shrinkable tube

8. Traction output part: the motor drives the rubber roller to pull and output the expanded heat-shrinkable tube

9. Finished product transmission output

WOLJIA designs and manufactures complete extrusion&expansion lines for producing Heat Shrink Tubing including pelletizers, extruders, expanders, tooling, and all auxiliary machines.

WOLJIA can offer you the most suitable product solution based on your demands, and customize your heat shrink tubing production line.