Sheet Extruder | Sheet Extrusion | Sheet Extrusion Line

Sheet Extruder | Sheet Extrusion | Sheet Extrusion Line

Sheet extrusion is a technique for making flat plastic sheets from a variety of resins. The thinner gauges are thermoformed into packaging applications such as drink cups, deli containers, produce trays, baby wipe containers and margarine tubs.

Sheet Extrusion Line for PE Sheet, PP Board Sheet, PC/PMMA Transparent Plate Sheet, PVC Plastic Sheet, PP/PS/PET Seedling Trays, PE Root Controller Sheet, PP/PS Blister Packing Sheet, Medical Grade Board Sheet, PE/EVA/PVC Waterproofing Membrane, PE/EVA/PVC Waterproofing Membrane, HDPE Geocell Sheet, HDPE Drain Board, ABS Board Sheet, ABS Refrigerator Board, Sanitary Ware Board, PC/PE/PP Hollow Lattice Board, PVC Transparent Soft Curtain, PVC Crystal Panel, PVC Wood Plastic Crust Foam Board, PVC Decorative Board, TPE/SBS/PVC Car Foot Mat, APET/PET/PETG/CPET Sheet

Main components of extrusion equipment: extruder -Quick screen changer -Solution metering pump-Sheet extrusion die-Three-roll calender-Edge trimming device/Cooling and shaping bracket-2 Roller Tractor -Cut-to-length output unloading or rewinding machine

The models of extruders are: SJ-75 extruder, SJ-90 extruder, SJ-120 extruder, SJ-150 extruder, SJ-180 extruder.

Quick Screen Changer, The filter mesh of 80-200 mesh can be woven, and the pressure can be increased during the extrusion process and the impurities in the raw material can be filtered out.

Melt Metering Pump: Control the metering of molten raw materials and evenly deliver them to the machine head.

Plastic Sheet Extrusion Die: the material flows evenly, and can manufacture sheets of different widths and thicknesses.

Three-roll calendar: The sheet extruded from the flat head has a high temperature, and is calendered by the three-roll calendar and gradually cooled. At the same time, it also plays a specific role in traction, adjusting the speed of each point of the board to be consistent to ensure the flatness of the board. According to the processing performance of different materials, three-roll calendars can be divided into flat three-roll calendars, vertical three-roll calenders, and 45-degree inclined three-roll calenders.

(Edge trimming device) Cooling and shaping bracket: A plate or sheet extruded from a die, the ends need to be cut off. Between the three-roll calender and the two-roll tractor, there are 10-20 stainless steel rollers with a diameter of 63 mm for cooling and conveying, so that the plate sheet can naturally dissipate heat in the air. The length of the cooling bracket is determined according to the thickness of the plate, so that the plate is cooled and formed.

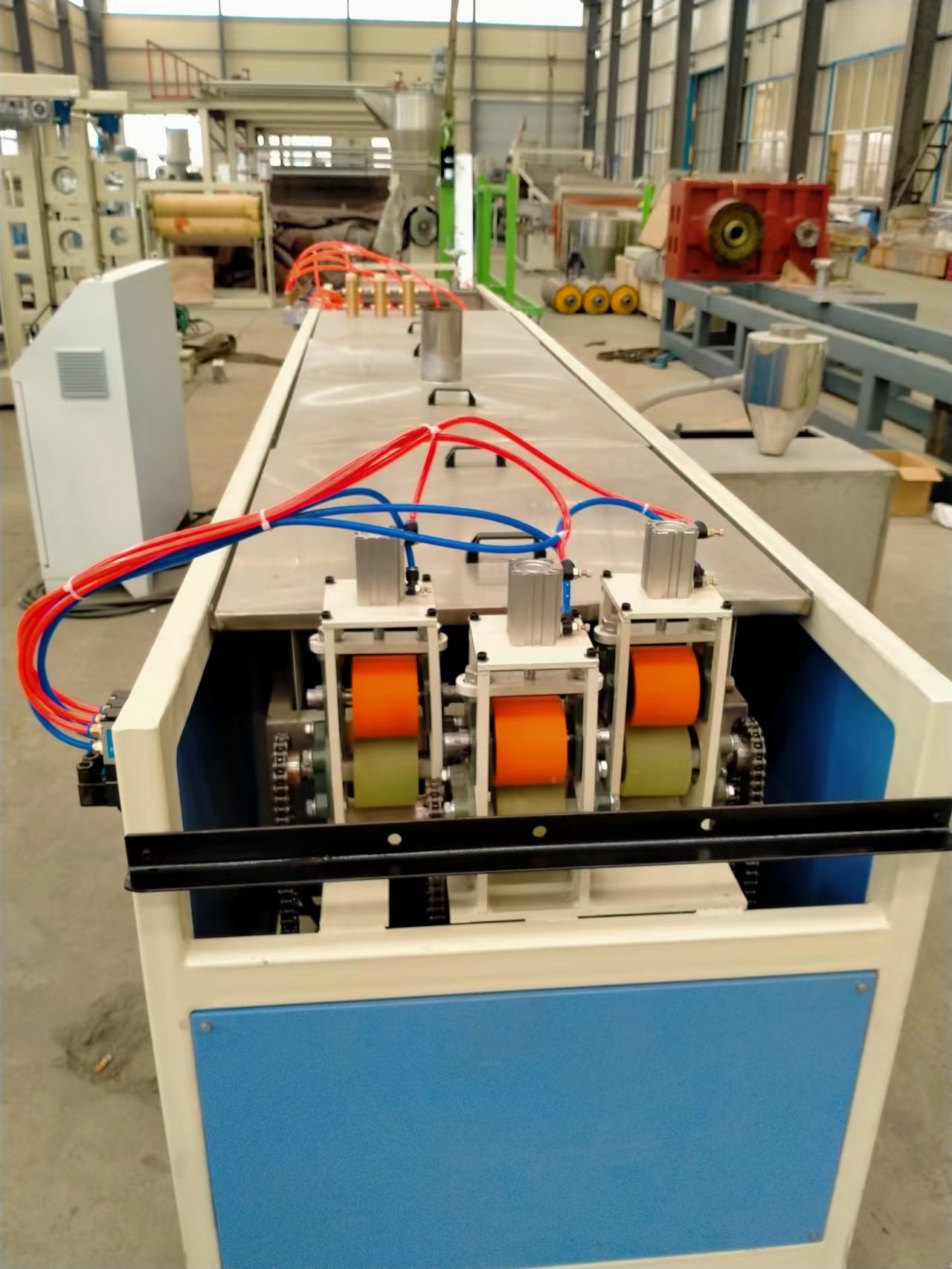

The 2-roller pulling machine is composed of 2 rollers, which evenly pulls the tube or sheet to the cutting device.

The 2-roller pulling machine is composed of 2 rollers, which evenly pulls the tube or sheet to the cutting device.

Fixed-length cutting and output unloading or rewinding machine: The hard plate or thick plate output by the tractor needs to be cut to a fixed length and conveyed for unloading. The soft board or sheet output by the tractor needs to be rolled into a cylindrical shape

The extrusion production line is equipped with automatic vacuum feeder or screw feeder

Equipped with drying hopper, the models are: 50KG, 75KG, 100KG, 150KG

Continuous heat shrinkable tubing production line | Continuous heat shrinkable tubing production machine | Heat Shrink Tube Extrusion Machine | Heat Shrink Tube Expansion Machine | Heat shrink tube production line | Heat Shrinkable Tubing Extruder&Expander

PE/EVA double-wall heat shrinkable tube production equipment | Dual-wall Heat Shrinkable Tubing Production Line | Double wall heat shrinkable tube with glue Extruder&Expander

Plastic-sheet-extruder | PE Sheet Extruder | PP Board Sheet Extruder | PC/PMMA Transparent Plate Sheet Extruder | PVC Plastic Sheet Extruder | PP/PS/PET Seedling Trays Extruder | PE Root Controller Sheet Extruder | PP/PS Blister Packing Sheet Production Equipment | Medical Grade Board Sheet Production Equipment | PE/EVA/PVC Waterproofing Membrane Extruder | HDPE Geocell Sheet Extruder | HDPE Drain Board Extruder | ABS Board Sheet extruder | ABS Refrigerator Board Extrusion Line | Sanitary Ware Board Extruder Production Line | PC/PE/PP Hollow Lattice Board Extruder Production Line | PVC Transparent Soft Curtain Extrusion Line | PVC Crystal Panel Production Line | PVC Wood Plastic Crust Foam Board Production Line | PVC Decorative Board Extruder | TPE/SBS/PVC Car Foot Mat Extruder | APET/PET/PETG/CPET Sheet Extruder/Extrusion Line

TPU/PA pneumatic hose | PE/EVA/FEP/PEEK precision small tube | HDPE insulation pipe | HDPE large diameter winding pipe | HDPE water supply pipe | PP plastic pipe | PERT floor heating pipe | PVC pipe | PVC threading pipe | MPP power tube | HDPE large diameter pipe | HDPE double wall corrugated pipe | PA nylon pipe

Wood Plastic Composite (WPC) Extrusion Production Line | PVC Gusset Plate Production Line/Gusset Plate Extrusion Line | PVC Wall Panel Extrusion Line | PVC Hanging Panel Extrusion Line | Bamboo Fiber Integrated Wall Board Extrusion Line | PVC windows and doors profile Extrusion Line

PET Bottle Flakes Granulator/Pelletizing Line | PE Recycling Granulator | 75 Parallel Twin-screw Modified Pelletizer | ABS Recycling Granulator | 65 Conical Twin-screw PVC Pelletizer | Double-machine Strand Pelletizer

The SWP-360 energy-saving crusher | SHR-L200/500 Mixer

Woljia is a high-tech enterprise engaged in the research and development, production, sales and technical services of various plastic machinery and plastic products.

Woljia is a high-tech enterprise engaged in the research and development, production, sales and technical services of various plastic machinery and plastic products. Specializing in the production of heat shrinkable tube production equipment and various auxiliary equipment for PE, EVA, PET, PVC, PEEK, FEP and other materials; Continuous extrusion and expansion production equipment for heat shrinkable tubing, Power busbar heat shrinkable tubing series production equipment, Electronic cable protection heat shrinkable tubing production equipment, Marine water pump waterproof double-wall heat shrinkable tubing production equipment, Environmentally friendly halogen-free heat shrinkable tubing production equipment, Medical equipment heat shrinkable tubing production equipment, Heat-shrinkable tube equipment for high-speed rail, electronic thin tube production equipment for computers, air conditioners, refrigerators and other electronic products, packaging heat-shrinkable tube equipment and other pipe production lines with memory.

Plastic Extruder,Plastic Pipe Production Equipment, Plastic Profile Production Equipment, PE, PP, PS, ABS, PC, PMMA, TPE, PET and other plastic sheet production equipment, crushers, mixers and other auxiliary equipment.

Plastic Extruder | Heat Shrink Tubing Extruder/Extrusion Line | Heat Shrink Tubing Expander/Expansion Line | Heat Shrink Tubing Extruder | Heat Shrink Tubing Expander | Heat Shrink Tubing Processing Equipment | Heat Shrink Equipment | Optical Fiber Heat Shrink Tube Extrusion Machine | Extruder for Tube of Evaporators and Condensers | PVC/PP/PE/EVA tubing Extruder/Expander | extruder/expander for heat shrink tubing | Plastic Expander | Extruder/Expander of Single-wall Tubing | heat shrink Extruder | Heat shrink Expander | heat-shrink tube extruding machine | Heat shrinkable tube expanding machine