Plastic Granulator | Plastic Granulating Line | Plastic Granulation Production Line | Plastic Recycling Granulating Production Line

Plastic Granulator | Plastic Granulating Line | Plastic Granulation Production Line | Plastic Recycling Granulating Production Line

Plastic Pelletizer | Plastic Pelletizing Machine | Pelletizing Line | Pelletizing Extrusion Line

The plastics processing industry relies on specialized machinery to cut and grind material to a specific size or shape. Granulators and pelletizers are commonly found in plastic processing plants.

However, they perform two very different tasks.

Granulator machines are used mainly to recycle plastics. They’re often found in plastic recycling plants or other manufacturing facilities where recycling scrap from their products can add up to significant cost savings. Other times, companies will purchase plastic scrap, use a granulator to chop it down to a specific size or shape, and then put the finished product back on the market for resale.

The size of the recycled granular flake varies depending on the screen size inside the machine. We often refer to this as the “back end” of the process as the material has been made and formed into one of thousands of plastic products such as bottles, car bumpers, and computer keyboards.

Unlike granulators, which chop up plastic that’s already been created, pelletizers are used in the manufacturing of plastics. Polymers are mixed and then extruded through a die face and come out in long spaghetti-like strands. They’re then fed into a pelletizer, which cuts the strands into small pellets whose size is based upon the customer’s product.

Plastic granulation is divided into raw material granulation and recycled material granulation: Synthetic resins are generally in powder form. In order to facilitate molding and processing, the resin needs to be mixed with various additives and plasticized into granules. This process is raw material granulation or modified granulation.<br> There is also a recyclable plastic granulation, which recycles waste plastics uniformly, and forms granules after crushing, cleaning, etc., so as to realize the reusability of resources.

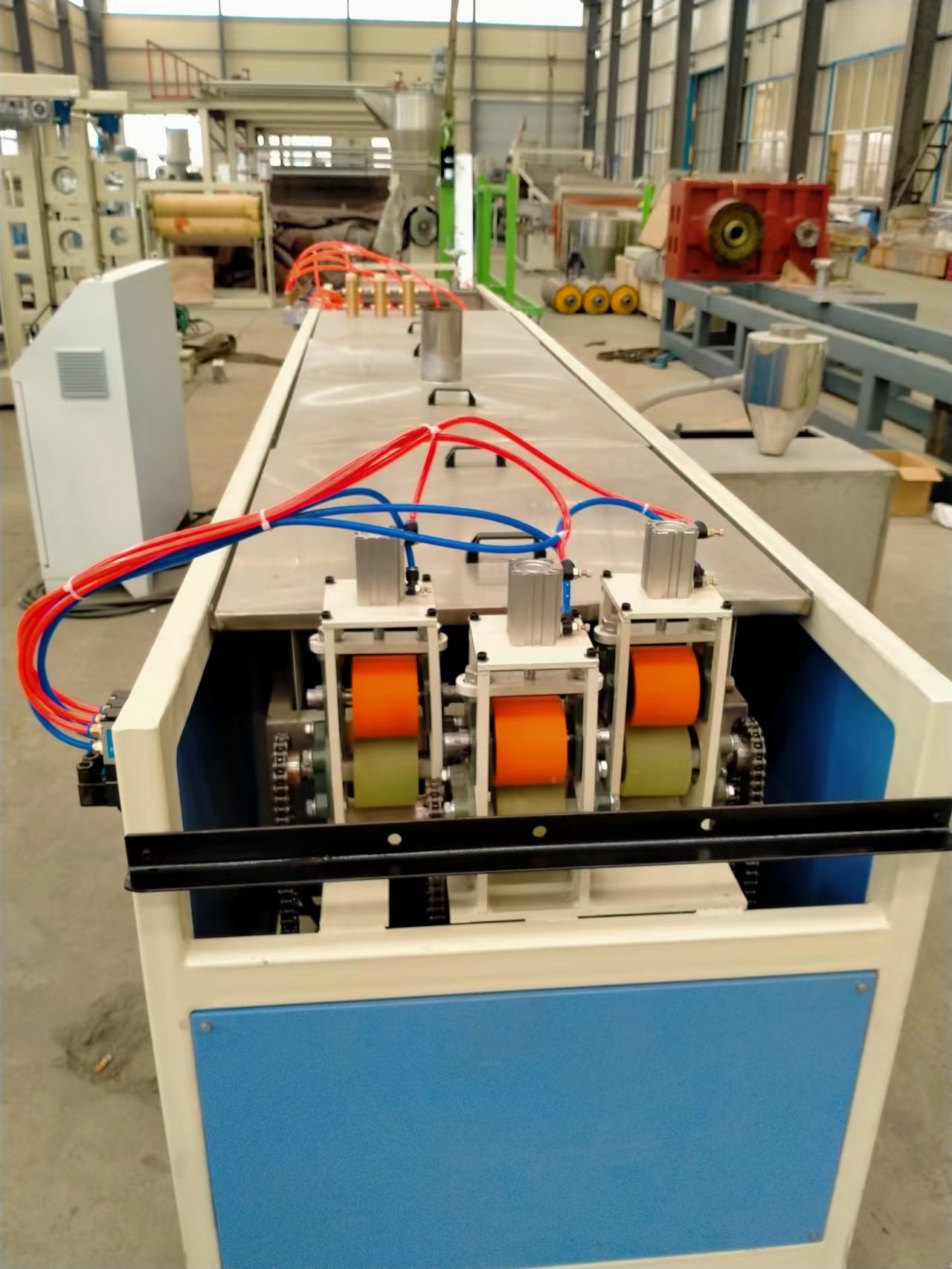

The main components of extrusion equipment: Extruder–granulation extrusion die–strand water cooling or ring-cut air cooling–vibrating screen–finished product

The extruder models are: CJWH65 Parallel Twin Screw Granulator, CJWH65 Parallel Twin Screw Granulator, SJSZ65 Conical Twin Screw Granulator, SJSZ80 Conical Twin Screw Granulator, SJ-90 single screw granulator, SJ-120 single screw granulator

Pelletizing die: pull pelletizing die, ring-cut pelletizing die

Cooling: water immersion cooling for pull bars, air cooling for ring cutting

Vibrating screen: The unqualified particles can be filtered out through the vibrating screen, so that the particle size of the finished product is uniform.

Continuous heat shrinkable tubing production line | Continuous heat shrinkable tubing production machine | Heat Shrink Tube Extrusion Machine | Heat Shrink Tube Expansion Machine | Heat shrink tube production line | Heat Shrinkable Tubing Extruder&Expander

PE/EVA double-wall heat shrinkable tube production equipment | Dual-wall Heat Shrinkable Tubing Production Line | Double wall heat shrinkable tube with glue Extruder&Expander

Plastic-sheet-extruder | PE Sheet Extruder | PP Board Sheet Extruder | PC/PMMA Transparent Plate Sheet Extruder | PVC Plastic Sheet Extruder | PP/PS/PET Seedling Trays Extruder | PE Root Controller Sheet Extruder | PP/PS Blister Packing Sheet Production Equipment | Medical Grade Board Sheet Production Equipment | PE/EVA/PVC Waterproofing Membrane Extruder | HDPE Geocell Sheet Extruder | HDPE Drain Board Extruder | ABS Board Sheet extruder | ABS Refrigerator Board Extrusion Line | Sanitary Ware Board Extruder Production Line | PC/PE/PP Hollow Lattice Board Extruder Production Line | PVC Transparent Soft Curtain Extrusion Line | PVC Crystal Panel Production Line | PVC Wood Plastic Crust Foam Board Production Line | PVC Decorative Board Extruder | TPE/SBS/PVC Car Foot Mat Extruder | APET/PET/PETG/CPET Sheet Extruder/Extrusion Line

TPU/PA pneumatic hose | PE/EVA/FEP/PEEK precision small tube | HDPE insulation pipe | HDPE large diameter winding pipe | HDPE water supply pipe | PP plastic pipe | PERT floor heating pipe | PVC pipe | PVC threading pipe | MPP power tube | HDPE large diameter pipe | HDPE double wall corrugated pipe | PA nylon pipe

Wood Plastic Composite (WPC) Extrusion Production Line | PVC Gusset Plate Production Line/Gusset Plate Extrusion Line | PVC Wall Panel Extrusion Line | PVC Hanging Panel Extrusion Line | Bamboo Fiber Integrated Wall Board Extrusion Line | PVC windows and doors profile Extrusion Line

PET Bottle Flakes Granulator/Pelletizing Line | PE Recycling Granulator | 75 Parallel Twin-screw Modified Pelletizer | ABS Recycling Granulator | 65 Conical Twin-screw PVC Pelletizer | Double-machine Strand Pelletizer

The SWP-360 energy-saving crusher | SHR-L200/500 Mixer

Woljia is a high-tech enterprise engaged in the research and development, production, sales and technical services of various plastic machinery and plastic products.

Woljia is a high-tech enterprise engaged in the research and development, production, sales and technical services of various plastic machinery and plastic products. Specializing in the production of heat shrinkable tube production equipment and various auxiliary equipment for PE, EVA, PET, PVC, PEEK, FEP and other materials; Continuous extrusion and expansion production equipment for heat shrinkable tubing, Power busbar heat shrinkable tubing series production equipment, Electronic cable protection heat shrinkable tubing production equipment, Marine water pump waterproof double-wall heat shrinkable tubing production equipment, Environmentally friendly halogen-free heat shrinkable tubing production equipment, Medical equipment heat shrinkable tubing production equipment, Heat-shrinkable tube equipment for high-speed rail, electronic thin tube production equipment for computers, air conditioners, refrigerators and other electronic products, packaging heat-shrinkable tube equipment and other pipe production lines with memory.

Plastic Extruder,Plastic Pipe Production Equipment, Plastic Profile Production Equipment, PE, PP, PS, ABS, PC, PMMA, TPE, PET and other plastic sheet production equipment, crushers, mixers and other auxiliary equipment.

Plastic Extruder | Heat Shrink Tubing Extruder/Extrusion Line | Heat Shrink Tubing Expander/Expansion Line | Heat Shrink Tubing Extruder | Heat Shrink Tubing Expander | Heat Shrink Tubing Processing Equipment | Heat Shrink Equipment | Optical Fiber Heat Shrink Tube Extrusion Machine | Extruder for Tube of Evaporators and Condensers | PVC/PP/PE/EVA tubing Extruder/Expander | extruder/expander for heat shrink tubing | Plastic Expander | Extruder/Expander of Single-wall Tubing | heat shrink Extruder | Heat shrink Expander | heat-shrink tube extruding machine | Heat shrinkable tube expanding machine