Extruder&Expander of Single-wall Heat Shrinkable Tubing

Extruder&Expander of Single-wall Heat Shrinkable Tubing

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process.

Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materials include metals, polymers, ceramics, concrete, modelling clay, and foodstuffs. Products of extrusion are generally called extrudates.

However, when the tubing is heat-shrunk, its thickness will increase, which will in turn increase its overall dielectric withstanding voltage. Good-quality tubing can expand to more than twice its size.

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

The main components of heat shrinkable tubing extrusion production line: Extruder — Extrusion Die — Cooling and Setting Water Tank — Tractor — Winder

The main components of the heat shrinkable tubing expansion production line: Unwinding stand—tube blank feeding–glycerin heating box–die positioning–vacuum control–water cooling–traction output

The extruder models are: SJ-45 extruder, SJ-55 extruder, SJ-65 extruder, SJ-75 extruder, SJ-90 extruder.

Heat shrinkable tube extrusion die: within a certain range, different specifications of molds can be replaced to produce products of different specifications.

There are two types of cooling and shaping water tanks: submerged cooling water tanks and vacuum cooling water tanks. The submerged cooling water tank is mainly used for extrusion cooling and shaping of small-sized heat shrinkable tubes. The vacuum cooling water tank is mainly used for extrusion cooling and shaping of large-sized heat shrinkable tubes.

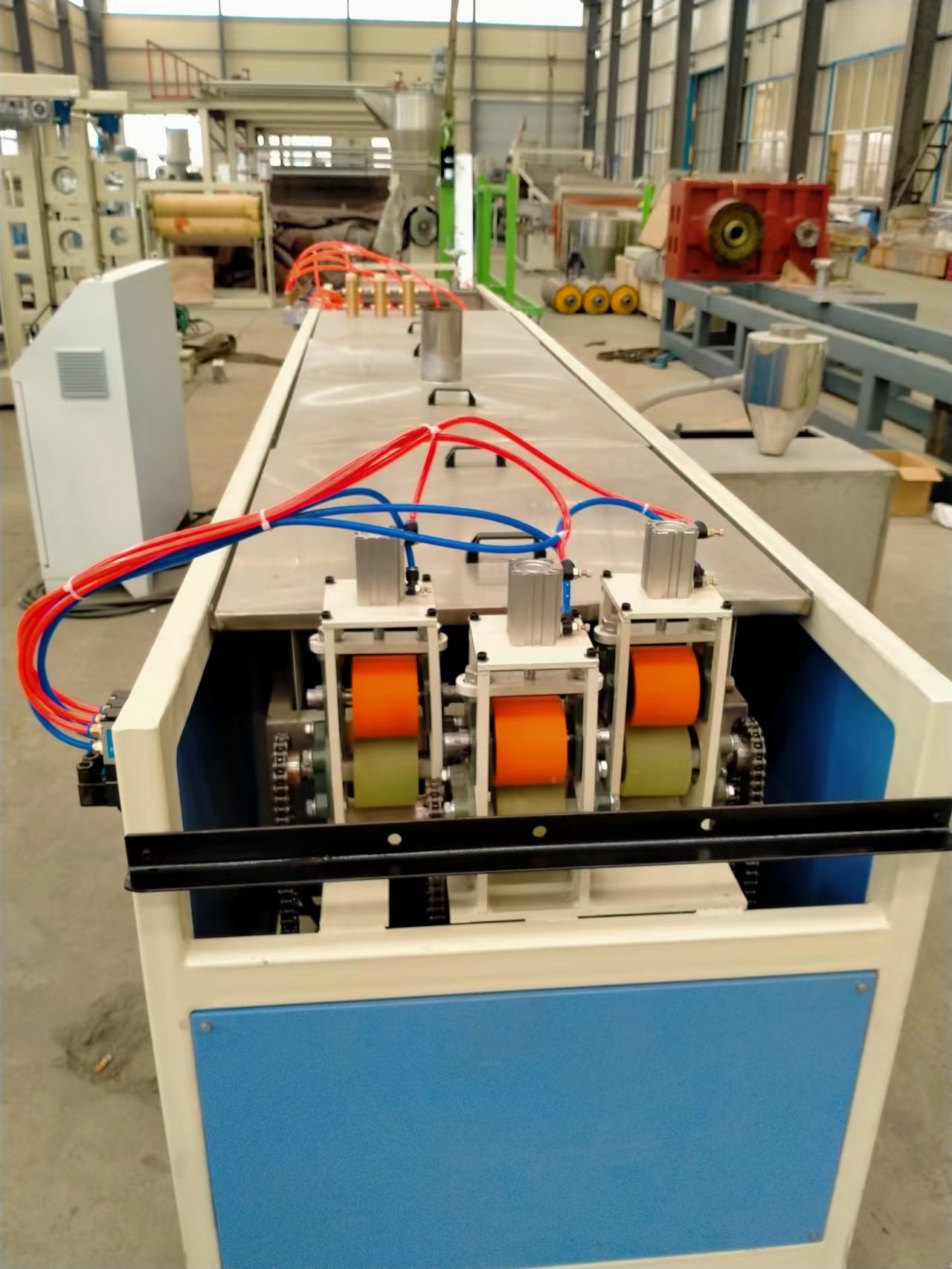

There are two types of tractors: The pair of roller traction machine (composed of 2 pairs of rubber rollers) is mainly used for extrusion traction of small-sized heat shrinkable tubes, The crawler tractor (composed of 2 rubber belts) is mainly used for extrusion traction of large-sized heat shrinkable tubes.

Rewinding machine: large diameter rewinding disc, to prepare for the next step (preparation for electron accelerator irradiation)

The extrusion production line is equipped with a fully automatic vacuum feeding machine.

Equipped with drying hopper, the models are: 25KG, 50KG, 75KG, 100KG

Unwinding stand: Pneumatic can be adjusted up and down, and the unwinding disc can rotate freely on it.

The feeding part of the tube blank: the transmission part is driven by the motor, and the rubber roller feeds the tube blank into the glycerin box

Glycerin heating box: electric heating of glycerin, heating the tube blank, the tube blank reaches a molten and high elastic state

Conveying part: the transmission part is driven by the motor to realize the continuous and uniform conveying of the tube blank in the glycerin box

Mold positioning part: used to install the expansion mold

Vacuum control part: control the vacuum size of the mold

Water cooling part: control the amount of water in the mold and cool the expanded heat shrinkable tube

Traction output part: the motor drives the rubber roller to pull the expanded heat shrinkable tube for output.

- Continuous heat shrinkable tubing production line | Continuous heat shrinkable tubing production machine | Heat Shrink Tube Extrusion Machine | Heat Shrink Tube Expansion Machine | Heat shrink tube production line | Heat Shrinkable Tubing Extruder&Expander

Continuous heat shrinkable tubing production line | Continuous heat shrinkable tubing production machine | Heat Shrink Tube Extrusion Machine | Heat Shrink Tube Expansion Machine | Heat shrink tube production line | Heat Shrinkable Tubing Extruder&Expander

PE/EVA double-wall heat shrinkable tube production equipment | Dual-wall Heat Shrinkable Tubing Production Line | Double wall heat shrinkable tube with glue Extruder&Expander

Plastic-sheet-extruder | PE Sheet Extruder | PP Board Sheet Extruder | PC/PMMA Transparent Plate Sheet Extruder | PVC Plastic Sheet Extruder | PP/PS/PET Seedling Trays Extruder | PE Root Controller Sheet Extruder | PP/PS Blister Packing Sheet Production Equipment | Medical Grade Board Sheet Production Equipment | PE/EVA/PVC Waterproofing Membrane Extruder | HDPE Geocell Sheet Extruder | HDPE Drain Board Extruder | ABS Board Sheet extruder | ABS Refrigerator Board Extrusion Line | Sanitary Ware Board Extruder Production Line | PC/PE/PP Hollow Lattice Board Extruder Production Line | PVC Transparent Soft Curtain Extrusion Line | PVC Crystal Panel Production Line | PVC Wood Plastic Crust Foam Board Production Line | PVC Decorative Board Extruder | TPE/SBS/PVC Car Foot Mat Extruder | APET/PET/PETG/CPET Sheet Extruder/Extrusion Line

TPU/PA pneumatic hose | PE/EVA/FEP/PEEK precision small tube | HDPE insulation pipe | HDPE large diameter winding pipe | HDPE water supply pipe | PP plastic pipe | PERT floor heating pipe | PVC pipe | PVC threading pipe | MPP power tube | HDPE large diameter pipe | HDPE double wall corrugated pipe | PA nylon pipe

Wood Plastic Composite (WPC) Extrusion Production Line | PVC Gusset Plate Production Line/Gusset Plate Extrusion Line | PVC Wall Panel Extrusion Line | PVC Hanging Panel Extrusion Line | Bamboo Fiber Integrated Wall Board Extrusion Line | PVC windows and doors profile Extrusion Line

PET Bottle Flakes Granulator/Pelletizing Line | PE Recycling Granulator | 75 Parallel Twin-screw Modified Pelletizer | ABS Recycling Granulator | 65 Conical Twin-screw PVC Pelletizer | Double-machine Strand Pelletizer

The SWP-360 energy-saving crusher | SHR-L200/500 Mixer

Woljia is a high-tech enterprise engaged in the research and development, production, sales and technical services of various plastic machinery and plastic products.

Woljia is a high-tech enterprise engaged in the research and development, production, sales and technical services of various plastic machinery and plastic products. Specializing in the production of heat shrinkable tube production equipment and various auxiliary equipment for PE, EVA, PET, PVC, PEEK, FEP and other materials; Continuous extrusion and expansion production equipment for heat shrinkable tubing, Power busbar heat shrinkable tubing series production equipment, Electronic cable protection heat shrinkable tubing production equipment, Marine water pump waterproof double-wall heat shrinkable tubing production equipment, Environmentally friendly halogen-free heat shrinkable tubing production equipment, Medical equipment heat shrinkable tubing production equipment, Heat-shrinkable tube equipment for high-speed rail, electronic thin tube production equipment for computers, air conditioners, refrigerators and other electronic products, packaging heat-shrinkable tube equipment and other pipe production lines with memory.

Plastic Extruder,Plastic Pipe Production Equipment, Plastic Profile Production Equipment, PE, PP, PS, ABS, PC, PMMA, TPE, PET and other plastic sheet production equipment, crushers, mixers and other auxiliary equipment.

Plastic Extruder | Heat Shrink Tubing Extruder/Extrusion Line | Heat Shrink Tubing Expander/Expansion Line | Heat Shrink Tubing Extruder | Heat Shrink Tubing Expander | Heat Shrink Tubing Processing Equipment | Heat Shrink Equipment | Optical Fiber Heat Shrink Tube Extrusion Machine | Extruder for Tube of Evaporators and Condensers | PVC/PP/PE/EVA tubing Extruder/Expander | extruder/expander for heat shrink tubing | Plastic Expander | Extruder/Expander of Single-wall Tubing | heat shrink Extruder | Heat shrink Expander | heat-shrink tube extruding machine | Heat shrinkable tube expanding machine