The process of producing heat-shrinkable tubing consists of three steps: extrusion, electron beam irradiation, and expansion.

For example, polyethylene is extruded into a tubular shape using an extruder and then cross-linked by a high-energy electron beam accelerator. Next, the cross-linked tube is softened in the heating zone and expanded radially by internal pressure or other means, and then cooled to fix the expanded shape as the final heat-shrinkable tube product.

Customize Your Solutions to Extrusion&Expansion for Heat Shrink Tubing

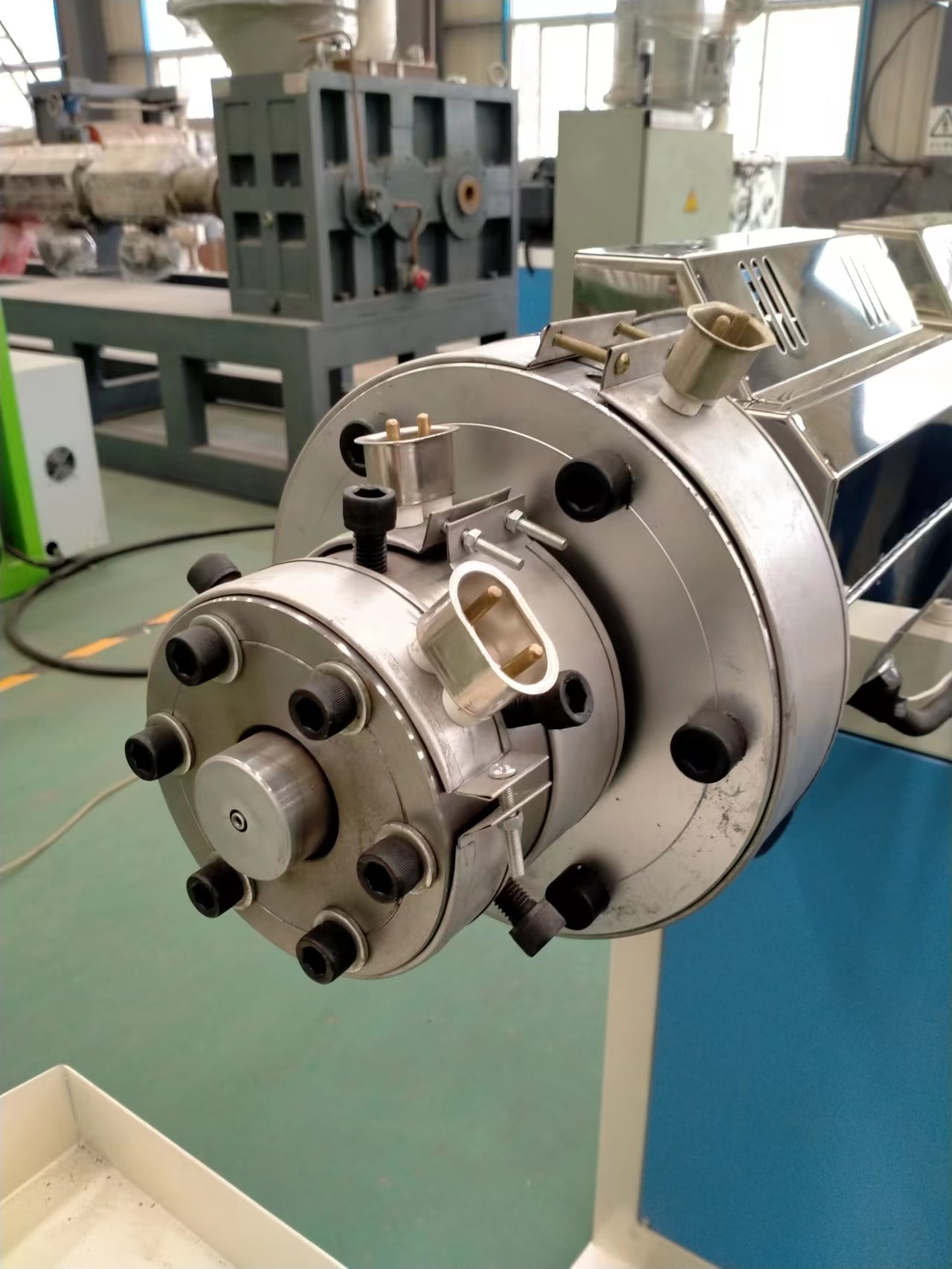

WOLJIA designs and manufactures complete extrusion&expansion lines for producing Heat Shrink Tubing including pelletizers, extruders, expanders, tooling, and all auxiliary machines.

WOLJIA can offer you the most suitable product solution based on your demands, and customize your heat shrink tubing production line.

Specializing in the production of heat-shrinkable tube production equipment and various auxiliary equipment for PE, EVA, PET, PVC, PEEK, FEP, and other materials;

Continuous extrusion and expansion production equipment for heat-shrinkable tubing,

Power busbar heat shrinkable tubing series production equipment,

Electronic cable protection heat shrinkable tubing production equipment,

Marine water pump waterproof double-wall heat shrinkable tubing production equipment,

Environmentally friendly halogen-free heat shrinkable tubing production equipment,

Medical equipment heat shrinkable tubing production equipment,

Heat-shrinkable tube equipment for high-speed rail, electronic thin tube production equipment for computers, air conditioners, refrigerators, and other electronic products, packaging heat-shrinkable tube equipment, and other pipe production lines with memory.

Plastic Extruder, Plastic Pipe Production Equipment, Plastic Profile Production Equipment,

PE, PP, PS, ABS, PC, PMMA, TPE, PET, and other plastic sheet production equipment, crushers, mixers, and other auxiliary