Heat shrink tube production equipment, heat shrink tube expanding machine, heat shrink tube expanding equipment, PE/EVA heat shrink tube production line, double wall heat shrink tube production equipment with rubber, PE high iron heat shrink tube production equipment, electronic tube heat shrink tube production, terminal heat shrink tube production equipment, EVA fiber heat shrink tube production equipment, low-pressure heat shrink tube production equipment, heat shrink tube production equipment, Electric high-pressure heat shrink tube production equipment, FEP/PEEK medical heat shrink tube expanding machine, PE packaging protection heat shrink tube production equipment.

An extruder that melts and extrudes the raw material through a die and then expands it with air pressure. The extruder can adjust the diameter, thickness, and length of the tubing according to the specifications.

It can produce single wall heat shrink tubing from various materials, such as polyolefin, fluoropolymer, elastomer, etc. Each material has different properties, such as flexibility, temperature resistance, chemical resistance, flame retardance, etc

The main components of heat shrink tubing extrusion production line: Extruder — Extrusion Die — Cooling and Setting Water Tank — Tractor — Winder

The main components of the heat shrink tubing expansion production line: Unwinding stand—tube blank feeding–glycerin heating box–die positioning–vacuum control–water cooling–traction output

Single Wall Heat Shrink Tubing Extrusion&Expansion Production Line

1. Heat Shrink Tubing Extruder Models:

SJ-30 extruder, SJ-45 extruder, SJ-50 extruder,

SJ-55 extruder, SJ-65 extruder, SJ-75 extruder,

SJ-90 extruder, SJ-120 extruder.

2. Heat Shrink Tubing Extrusion Die:

Within a certain range, dies of different specifications can be replaced to produce products of different specifications.

3. Two types Cooling and Shaping Water Tanks:

Immersion cooling and shaping water tank and vacuum cooling and shaping water tank.

Immersion cooling and shaping water tank is mainly used for extrusion cooling and shaping of small-size heat shrink tubing,

Vacuum cooling and shaping tank is mainly used for extrusion cooling and shaping large-size heat-shrink tubing.

4. Two types Tractors :

Twin-roll tractor (composed of two pairs of rubber rollers) is mainly used for the extrusion and traction of small-size heat shrink tubing,

Crawler tractor (two traction tracks composed of a rubber belt or rubber block) is mainly used for the extrusion and traction of large-size heat shrink tubing

5. Winding Machine:

Large-diameter winding machines are used to prepare for the next step (preparation for electron accelerator irradiation) Small-size heat shrink tubing needs to be plied and winded to the winding plate together and then the branching machine separates the tubing after irradiation.

Drying&Feeding Machine

6. Single Wall Heat Shrink Tubing Extrusion Production Line is equipped with an automatic vacuum feeding machine with a drying hopper, The models are: 25kG, 50kG, 75kG, 100kG

No.1 The main equipment components:

Heat Shrink Tubing Extruder – Extrusion Die – Cooling&Shaping Water Tank -Roll Tractor-Plying&Winding Machine, Branching Machine

Model SJ-30 for Φ0.5-Φ10mm, 5-20mtrs/min

Model SJ-45 for Φ6-Φ20mm, 8-40mtrs/min

No.2 The main equipment components:

Heat Shrink Tubing Extruder – Extrusion Die – Cooling&Shaping Water Tank -Belt Tractor–Winding Machine

Model SJ-50 for Φ20-Φ40mm, 5-20mtrs/min

Model SJ-55 for Φ30-Φ60mm, 5-18mtrs/min

No.3 The main equipment components:

Heat Shrink Tubing Extruder – Extrusion Die – Cooling&Shaping Water Tank -Belt Tractor–Winding Machine

Model SJ-65 for Φ60-Φ120mm, 4-10mtrs/min

Model SJ-75 for Φ100-Φ180mm, 4-10mtrs/min

No.4 The main equipment components:

Heat Shrink Tubing Extruder – Extrusion Die – Cooling&Shaping Water Tank-Shaping Die-Belt Tractor-Winding Machine/Winding&Plying Machine/Cutting Machine

Model SJ-90 for Φ150-260mm, 3–10mtrs/min

Model SJ-120 for Φ200-Φ300mm, 3-10mtrs/min

Single Wall Heat Shrink Tubing Expansion Production Line equipment introduction: This production line uses glycerin as a heat conduction medium, Expansion and setting equipment is carried out by combining negative pressure (vacuum) and positive pressure (inner air).

Single Wall Heat Shrink Tubing Expansion Line equipment introduction:

This production line uses glycerin as a heat conduction medium, Expansion and setting equipment is carried out by combining negative pressure (vacuum) and positive pressure (inner air).

1. Unwinding stand: made of the square tube or section steel, the unwinding reel rotates freely on it

2. Tube Billet Traction and Feeding Part: driven by the motor, the rubber roller feeds the tube billet into the glycerin box

3. Glycerin Heating Tank: electric heating of glycerin to heat the tube blank, so that the irradiated tube blank reaches a molten high-elastic state

4. Glycerin Heating and Conveying Section: the transmission part is driven by the motor to realize the continuous and uniform transportation of the tube billet in the glycerin tank

5. Die Positioning Part: used to install expansion die

6. Vacuum Control Part: control the vacuum size of the die

7. Water Cooling Part: control the water volume of the die, and cool the expanded heat shrink tubing

8. Traction Output Part: the motor drives the rubber roller to pull and output the expanded heat shrink tubing

9. Finished product Transport Output

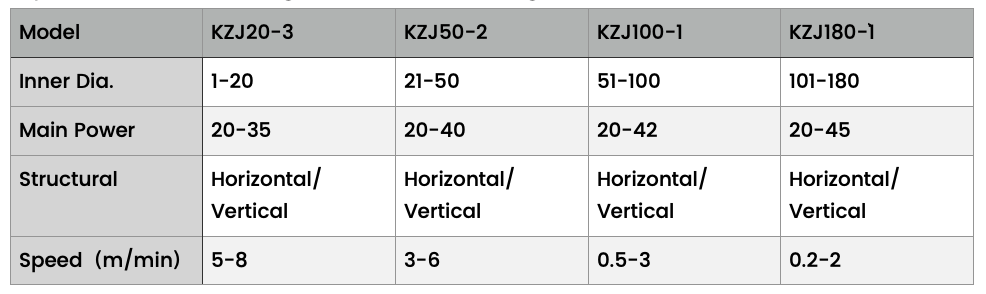

KZJ20-3 1 out of 3 Single-Wall Heat Shrink Expansion Production Line

The kind of Expander can expand three different specifications or three tubes of the same specification at the same time KZJ50-2The kind of Expander can expand two different specifications or two tubes of the same specification at the same time

KZJ50-2 1 out of 2 Single-Wall Heat Shrink Expansion Production Line

The kind of Expander can expand two different specifications or two tubes of the same specification at the same time

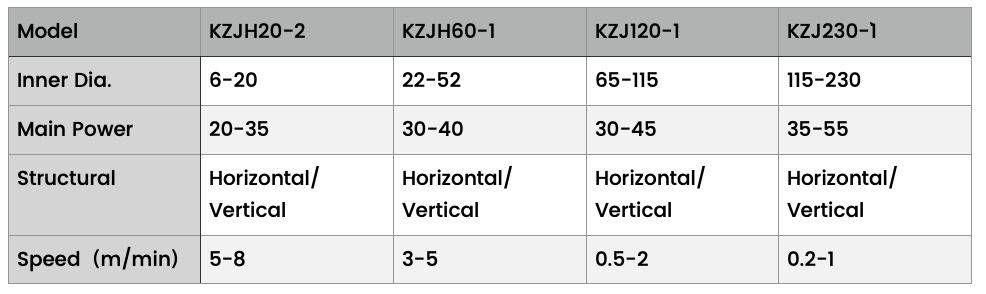

KZJH-2 1 out of 2 Heat Shrink Expansion Production Line

The kind of Expander can expand two different specifications or two tubes of the same specification at the same time

specializing in the production of heat shrink tubing production equipment and various auxiliary equipment for PE, EVA, PET, PVC, PEEK, FEP, and other plastic materials

Continuous extrusion and expansion production equipment for heat shrink tubing,

Power busbar heat shrink tubing line production equipment,

Electronic cable protection heat shrink tubing line production equipment,

Marine water pump waterproof dual wall heat shrink tubing line production equipment,

Environmentally friendly halogen-free heat shrink tubing line production equipment

Medical equipment heat shrinkable tubing production equipment,

Heat shrink tubing line equipment for high-speed rail, electronic thin tube production equipment for computers, air conditioners, refrigerators, and other electronic products, packaging heat-shrinkable tube equipment, and other tube production lines with memory.

and other plastic sheet production equipment, crushers, mixers, and other auxiliary