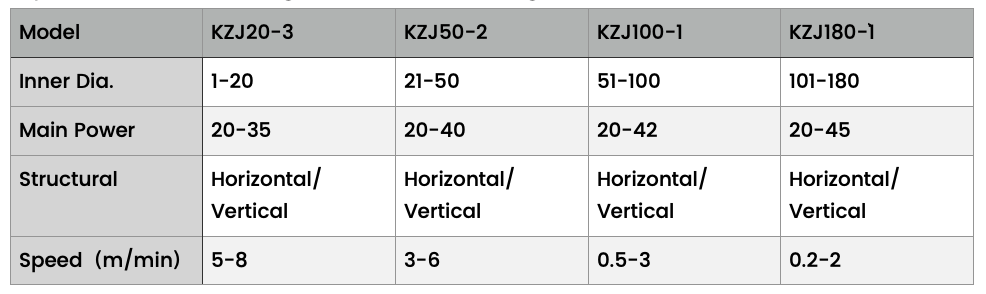

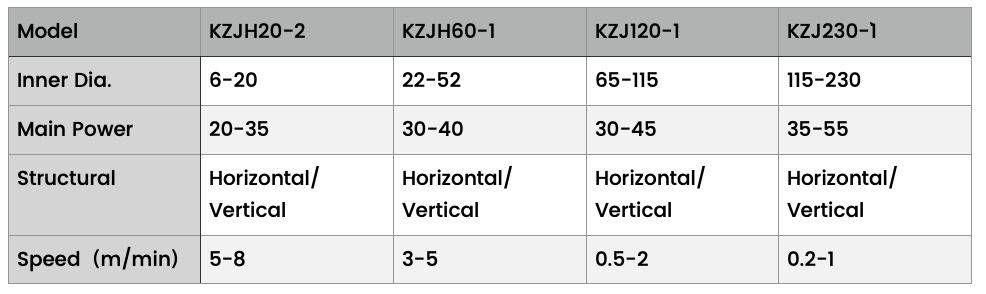

Specification Range Optional Expander Model of Heat Shrink Tubing

The production speed is for reference only, the specific speed depends on the tubes type, size, and wall thickness

Expander for Low Voltage Heat Shrink Tubing

Expander for Medium/High Voltage Heat Shrink Tubing

Expander/Expansion Line for PE LV/MV/HV Heat Shrink Tubing Heat shrink tubing expansion production line Thin Wall Tubing, Busbar Sleeve, Dual Wall Tubing, Medium/Heavy Wall Tubing, Insulated Tubing, Productive Tubing

Heat shrinkable tubing expansion production line equipment introduction:

This production line uses glycerin as a heat conduction medium, Expansion and set equipment are carried out by combining negative pressure (vacuum) and positive pressure (inner air).

It mainly consists of the following parts:

1. Unwinding stand: made of the square tube or section steel, the unwinding reel rotates freely on it

2. Tube billet traction and feeding part: driven by the motor, the rubber roller feeds the tube billet into the glycerin box

3. Glycerin heating box: electric heating of glycerin to heat the tube blank, so that the irradiated tube blank reaches a molten high-elastic state

4. The conveying part of the glycerin heating box: the transmission part is driven by the motor to realize the continuous and uniform transportation of the tube billet in the glycerin box

5. Mold positioning part: used to install expansion mold

6. Vacuum control part: control the vacuum size of the mold

7. Water cooling part: control the water volume of the mold, and cool the expanded heat shrinkable tube

8. Traction output part: the motor drives the rubber roller to pull and output the expanded heat-shrinkable tube

9. Finished product transmission output

WOLJIA designs and manufactures complete extrusion&expansion lines for producing Heat Shrink Tubing including pelletizers, extruders, expanders, tooling, and all auxiliary machines. We can offer you the most suitable product solution based on your demands, customize your heat shrink tubing production line.