Extruder & Expander

Extruder&Expander of Single-wall Heat Shrinkable Tubing

- The main components of heat shrinkable tubing extrusion production line: Extruder — Extrusion Die — Cooling and Setting Water Tank — Tractor — Winder

- Continuous heat shrinkable tubing production line | Continuous heat shrinkable tubing production machine | Heat Shrink Tube Extrusion Machine | Heat Shrink Tube Expansion Machine | Heat shrink tube production line | Heat Shrinkable Tubing Extruder&Expander

Extruder&Expander for Dual-wall Heat Shrinkable Tubing

- Main components of Dual-Wall heat shrinkable tubing extrusion equipment: Outer Layer Extruder+Inner Layer Hot Melt Adhesive Extruder–Composite Extrusion Die–Cooling &Shaping Water Tank—Tractor—Winder

- PE/EVA double-wall heat shrinkable tube production equipment | Dual-wall Heat Shrinkable Tubing Production Line | Double wall heat shrinkable tube with glue Extruder&Expander

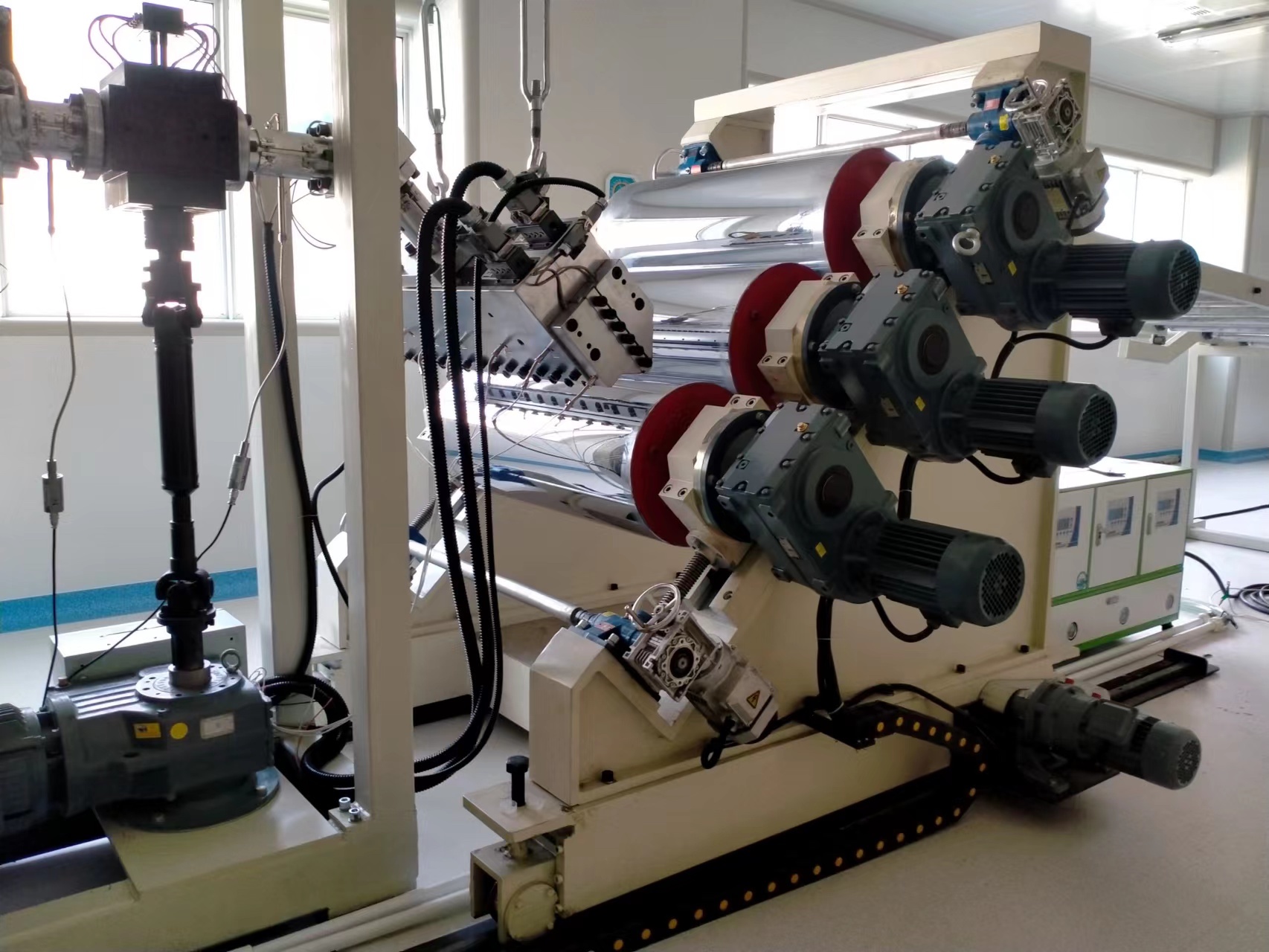

Sheet Extruder | Sheet Extrusion | Sheet Extrusion Line

- Main components of extrusion equipment: extruder -Quick screen changer -Solution metering pump-Sheet extrusion die-Three-roll calender-Edge trimming device/Cooling and shaping bracket-2 Roller Tractor -Cut-to-length output unloading or rewinding machine

- Plastic-sheet-extruder | PE Sheet Extruder | PP Board Sheet Extruder | PC/PMMA Transparent Plate Sheet Extruder | PVC Plastic Sheet Extruder | PP/PS/PET Seedling Trays Extruder | PE Root Controller Sheet Extruder | PP/PS Blister Packing Sheet Production Equipment | Medical Grade Board Sheet Production Equipment | PE/EVA/PVC Waterproofing Membrane Extruder | HDPE Geocell Sheet Extruder | HDPE Drain Board Extruder | ABS Board Sheet extruder | ABS Refrigerator Board Extrusion Line | Sanitary Ware Board Extruder Production Line | PC/PE/PP Hollow Lattice Board Extruder Production Line | PVC Transparent Soft Curtain Extrusion Line | PVC Crystal Panel Production Line | PVC Wood Plastic Crust Foam Board Production Line | PVC Decorative Board Extruder | TPE/SBS/PVC Car Foot Mat Extruder | APET/PET/PETG/CPET Sheet Extruder/Extrusion Line

Plastic Extruder | Pipe Extruder | Pipe Extrusion Line

Plastics extrusion, Plastic pipe extrusion:It is to add granular or powdery plastic from the hopper into the extruder, heat it into a molten material flow, and the thrust of the screw rotation makes the molten material enter the pipe mold through the annular channel of the machine head to form a pipe, which is cooled and shaped into a pipe.

The main components of extrusion equipment: extruder — pipe extrusion die — cooling and shaping water tank — tractor — (cutting) winding machine- TPU/PA pneumatic hose | PE/EVA/FEP/PEEK precision small tube | HDPE insulation pipe | HDPE large diameter winding pipe | HDPE water supply pipe | PP plastic pipe | PERT floor heating pipe | PVC pipe | PVC threading pipe | MPP power tube | HDPE large diameter pipe | HDPE double wall corrugated pipe | PA nylon pipe

Plastic Extruder | Profile Extruder | Profile Extrusion Line

Plastics extrusion, Plastic pipe extrusion:It is the process of adding granular or powdery plastic from the hopper to the extruder, heating it into a molten material stream, and the thrust of the screw rotation makes the molten material enter the profile mold through the machine head to form the required shape, and then it is cooled and shaped into a profiled process.

- The main components of extrusion equipment: Extruder — Profile Extrusion Die — Cooling and Forming Platform — Tractor — Cutting

- Wood Plastic Composite (WPC) Extrusion Production Line | PVC Gusset Plate Production Line/Gusset Plate Extrusion Line | PVC Wall Panel Extrusion Line | PVC Hanging Panel Extrusion Line | Bamboo Fiber Integrated Wall Board Extrusion Line | PVC windows and doors profile Extrusion Line

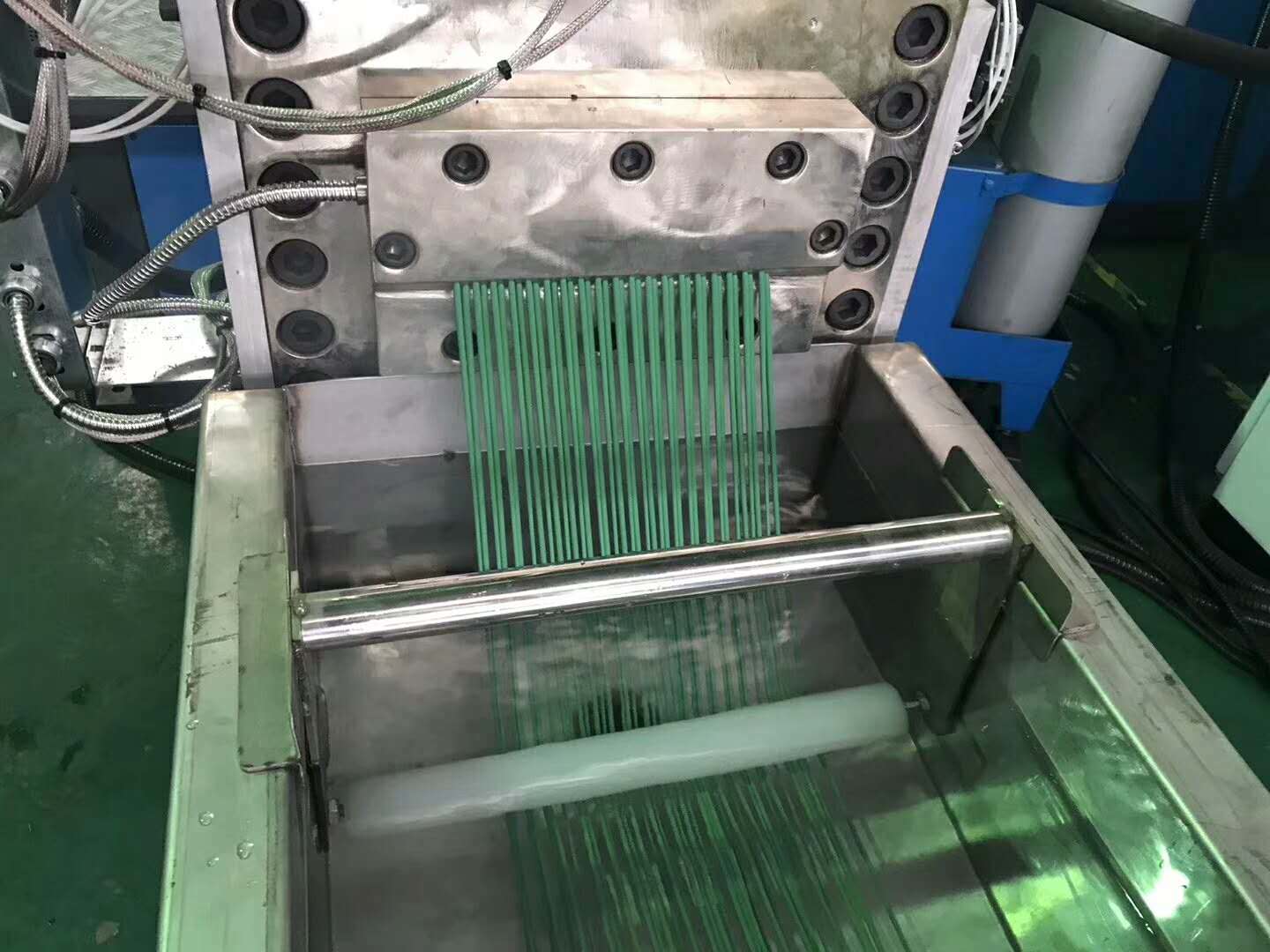

Plastic Granulator | Plastic Granulating Line | Plastic Pelletizer | Plastic Pelletizing Machine

Plastic granulation is divided into raw material granulation and recycled material granulation: Synthetic resins are generally in powder form. In order to facilitate molding and processing, the resin needs to be mixed with various additives and plasticized into granules. This process is raw material granulation or modified granulation.

There is also a recyclable plastic granulation, which recycles waste plastics uniformly, and forms granules after crushing, cleaning, etc., so as to realize the reusability of resources.- The main components of extrusion equipment: Extruder–granulation extrusion die–strand water cooling or ring-cut air cooling–vibrating screen–finished product

- PET Bottle Flakes Granulator/Pelletizing Line | PE Recycling Granulator | 75 Parallel Twin-screw Modified Pelletizer | ABS Recycling Granulator | 65 Conical Twin-screw PVC Pelletizer | Double-machine Strand Pelletizer

Plastic Auxiliary Machine | Energy Saving Machine | Mixer

SHR-L200/500 Mixer

- It is used for batching, mixing, drying, coloring and other processes of various plastics. It is an essential equipment for the production of wood-plastic products.

- Hot mixing has the functions of self-friction, electric heating and water volatilization

- It has the characteristics of compact structure and convenient use.

- The SWP-360 energy-saving crusher | SHR-L200/500 Mixer